WELCOME TO TRANSKINGUSA.COM

From its humble beginnings, Transking has quickly gained a reputation in the transport industry as one of a “do-er”. Transking wanted much safer, more efficient products for the transport industry.

Through comprehensive and extensive research and development Transking has come up with innovative products that will help the ever-growing need for a safer transport industry. Transking’s award-winning world-first products designed in Australia have now been accepted and adopted by many leading transport companies.

For over 25 years Transking have been developing custom Safety equipment for trucks and trailers.

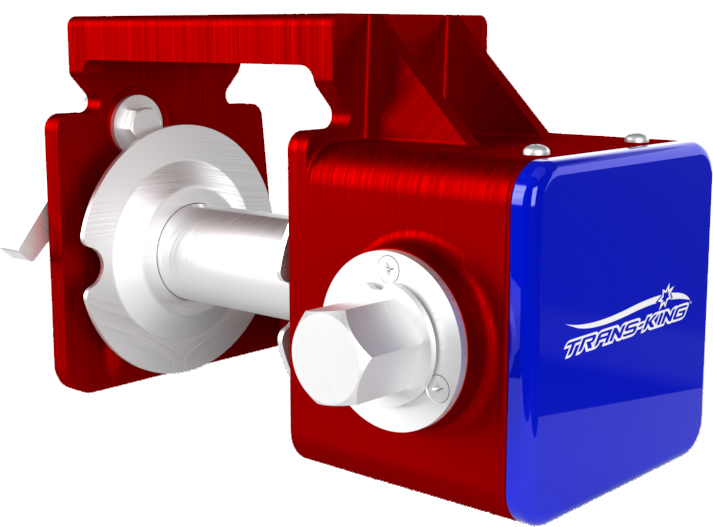

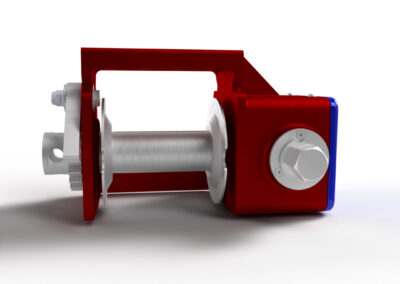

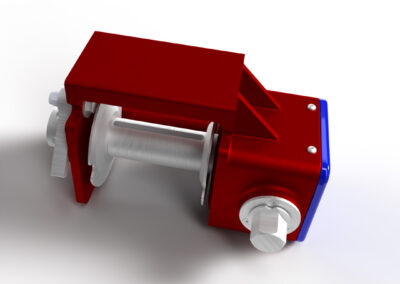

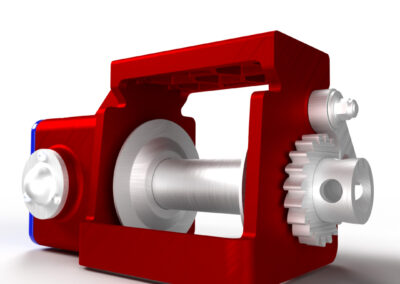

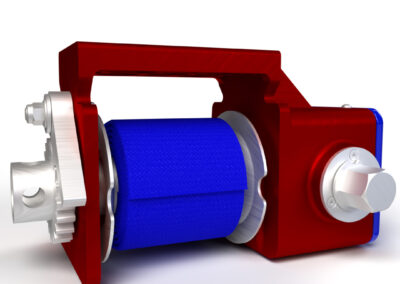

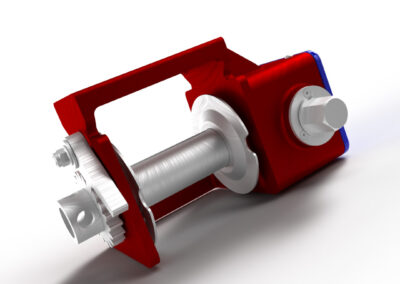

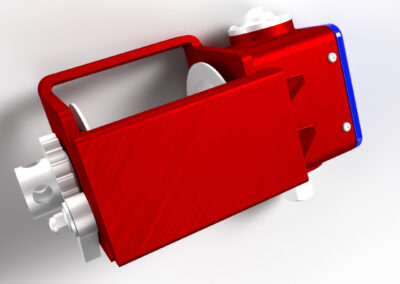

TRANSKING TIGHTWINDERTM

“THE FASTEST TIEDOWN WINCH”

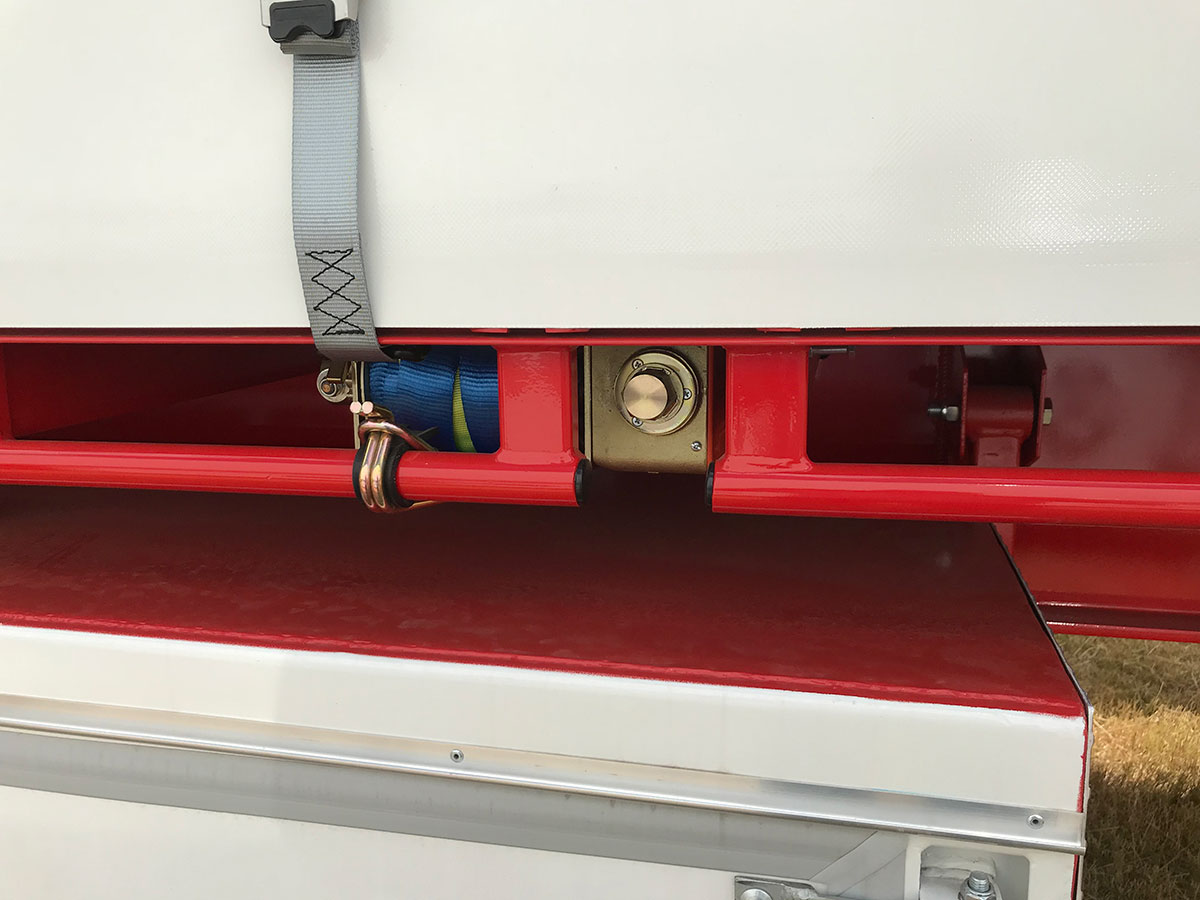

Transking TightwinderTM installed under the goose neck and over the drive for easier and safer access. Australian model shown.

View an Interactive 3D model of the Transking TightwinderTM

TRANSKING WOULD LIKE TO THANK THE MID-AMERICA TRUCKING SHOW FOR THE OPPORTUNITY TO SHOWCASE OUR AWARD WINNING PRODUCTS

For updates please subscribe to the Transking USA newsletter

This very practical product does it all!

- It creates long-term savings

- Faster turn-around, saving money

- Greatly reduced risk of injury

- Reduced occupational health and safety claims

- Greatly reduced winch bar kick back

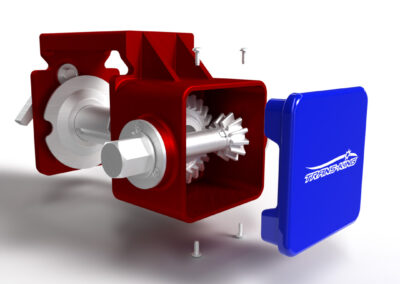

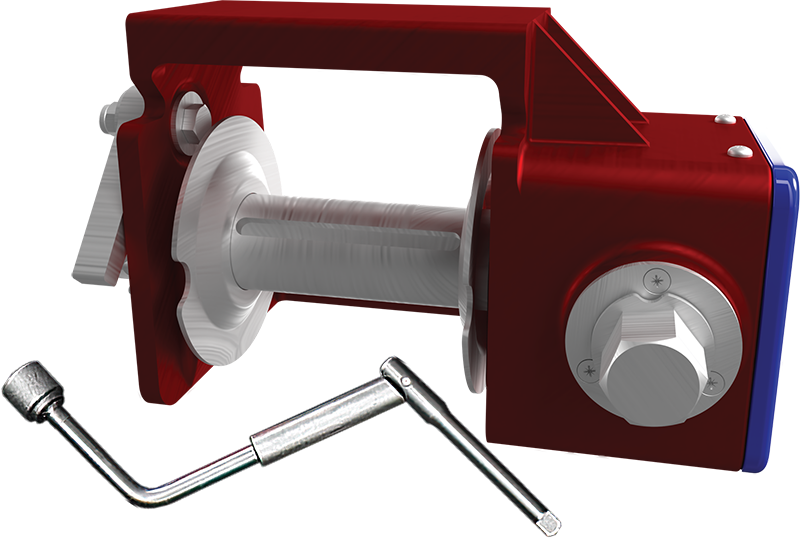

Tightwinder’s robust construction consists of a heavy-duty cast gearbox with machine finished surfaces and a heavy-duty pressed body designed to eliminate twist and distortion in normal operating conditions.

The strap through shaft is machined to take 2 interference fitting pressed strap guide plates to ensure smooth, reliable operation. The heavy-duty, bevelled gears are machine finished to the through shaft, which eliminates gear run out and enables smooth gear mesh.

The Transking TightwinderTM was originally developed to access difficult to get to places.

After many years Transking have further developed the world’s first two to one reduction angle drive load binder for trucks and trailers, it fits into a standard slide track and has a rotating gear head if required.

It has been the load security system of choice of many transport operators. It is up to four tonne rated to Australian standards and will take 50 mm 75m and 100mm strap. It has very little kick back when releasing tension, further reducing the possibility of injury and insurance claims, Its 1¼ inch (wheel nut socket) virtually eliminates the possibility of bar slippage its two to one reduction gear box makes it so easy to obtain strap tension safer.

The Transking TightwinderTM (Tiedown Winch / Loadbinder) is a carefully engineered piece of equipment designed to give years of service and reduce manual input effort from drivers and operators.

“SECURE YOUR LOAD IN HALF THE TIME”

Beyond the safety application Transking believe that the use of the Transking TightwinderTM can save up to 50% of loading time.

ENGINEERING FEATURES

Service:

- Minimal service required

- In muddy conditions remove strap and hose housing as required, dry strap and refit accordingly

- Can save you money and Insurance claims

Safety:

- Transking recommends that the gearbox bolts should be checked for tightness occasionally and that undamaged straps be used at all times.

- Always remember to protect straps with a sleeve over sharp surfaces.

The Transking TightwinderTM is fitted with a 1¼ Inch single hex head drive shaft which also suits a 1¼ Inch wheel brace socket should it be required.

The Australian model is rated at 8800lbs.

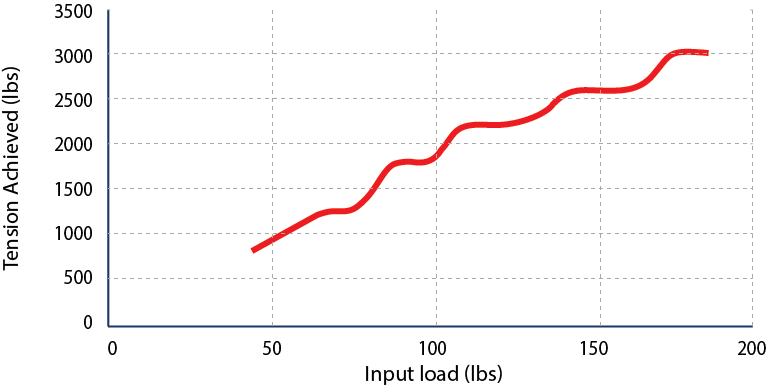

TEST REQUIREMENTS & PROCEDURES

The test procedure included a range of loads from 44-187lbs (20-85kg) applied at 90° to the line of action using a 15.75 inches (400mm) bar. Handle input force and strap tension achieved were recorded.

The unit was tested at a variety of handle loads to observe how the altered gear ratio affected the strap tension.

Below is a table of the results from the tests at a variety of input loads, the load was applied at approximately 15.75 inches (400mm) from the center of rotation.

| Load Applied to Handle (Ibs) | Input Moment (ft.lbs) | Strap Tension Achieved (Ibs) |

| 44 | 58 | 829 |

| 55 | 72 | 1023 |

| 66 | 87 | 1232 |

| 77 | 101 | 1290 |

| 88 | 116 | 1766 |

| 99 | 130 | 1795 |

| 110 | 145 | 2167 |

| 121 | 159 | 2174 |

| 132 | 174 | 2260 |

| 143 | 188 | 2542 |

| 154 | 203 | 2555 |

| 165 | 217 | 2604 |

| 176 | 232 | 2963 |

| 187 | 246 | 2963 |

Input Load vs. Tension Achieved

Interactive 3D model

2 to 1 reduction

1¼ inch drive socket

No more slipping bars

Reduce the injury risk

Maximum input 150 foot lbs = 2,100 lbs strap tension

IMAGE GALLERY

PROUDLY DESIGNED AND ENGINEERED IN AUSTRALIA FOR THE AMERICAN MARKET

Available through Transking

Contact Transking Founder and Director Lindsay King

+61 419 404 788 – Email info@transkingusa.com

PLEASE NOTE

Transking recommends and insists safe and proper procedure is followed while operating Transking’s products, including correct stands, wearing of correct PPE (personal protective equipment). This will reduce the injury risk of the operator.

“SECURE YOUR LOAD IN HALF THE TIME”

How and Why Cameron Logistics are using Transking Products

As standard Cameron Logistics specify Hendrickson HNL 7 INTRAAX suspension and axles with a 1.2 million kilometre-warranty. Included are the Transking TightwinderTM winches and Quickstrap MK II.

The Quickstrap system eliminates, according to Shane Coates, Glen Cameron Group Asset Manager, the need for drivers to climb steps so that they can pass or throw straps over the load.

“It can now be done safely with little effort from the ground using this system,” he says. “The driver just hooks the load binder strap into the Quickstrap using an extension pole and then pulls the strap across the load from the other side of the vehicle.”

Aside from the inherent efficiencies involved in their use, the Transking tiedown winches, according to Greg, are most of all safe and make for a great initiative.

“As a process, it requires less effort of the driver to realize more down force than a standard drum winch,” he says. “The cantilever winch handle and clockwise rotation of the tensioner is devised to greatly reduce the risk of drivers slipping and hitting their face on the side of the vehicle. We now standardize the Quickstrap and Tightwinder product across our entire fleet.”

Feedback from week 1 of Transking Tightwinder trial by Pickering Transport Group

You have made a great change to peoples lives already ~ Tony Ray

Just made the job so much easier, as stated over drive and tri axles particularly. Used to bring my electric drill with a socket on 150mm extension and wind up straps automatically. Tightwinder has made unstrapping safer and winding straps in better for my old arthritic hands, am very impressed and very happy ~ Steve Kallisch

Tightwinder is great, the load hadn’t moved… they’re excellent over the drive guards where you can struggle with a bar to get in the binder hole. 10 out of 10! ~ Pongo

Copy Southbound Podcast

Episode 56 – Lindsay King

Transking founder Lindsay King interview Copy Southbound Podcast

Some people go through life leaving a massive impact and Lindsay King is one of those people. From an early start as a motor mechanic, Lindsay moved into express freight before getting a managerial role with the Overnighters in his late 20’s. His innovative ideas helped develop the legendary Batmobiles into transport folklore before he moved onto Vawdrey Trailers where he left a legacy in trailer design that will remain for years to come. We take our hat off to him and we know you will to.

WHEN SAFETY MATTERS… IT ALWAYS DOES!

Safety is an integral part of the transport industry. If companies are not taking all possible steps to minimise and mitigate risks, they are leaving themselves open to workplace injuries and potential legal actions.

Transking’s philosophy is to develop innovative products to improve the safety throughout the transport industry. Transking’s innovative products are designed to reduce risks to the drivers and operators, at the same time, improving productivity.

WHAT JUST A FEW OF TRANSKING’S AUSTRALIAN CUSTOMERS SAY

Ron Finemore Transport

We have had positive feedback from both the drivers and warehouse personnel as both the Tightwinder tiedown winch and the Quickstrap system together make the loading process safer and more efficient. We recommend and endorse the Transking products and are extremely happy with the aftersales support way Transking has helped our business stay safer.

The Glen Cameron Group

The Glen Cameron Group has been a customer of Transking for many years. Our company uses Transking TightwinderTM tiedown winches across a large number of our fleet and are extremely happy with the quality, reliability, performance and service.

Gilders Transport & Logistics Pty Ltd

Gilders have been using the Transking TightwinderTM in our interstate operations for over fifteen years. During that time, we have found them to be easy and very safe to use, eliminating injury through bar slippage while securing loads. We also use the Transking Quickstrap product, which also reduces loading time.

Mainfreight Transport

The Tightwinder should be mandatory on all winch strap systems. The configuration caters for all sorts of vehicle and body designs and we have made the system mandatory in all our new 8 Double builds through Vawdrey.

Hannah’s Haulage

We mounted the Tightwinder units tucked up under the floor of the trailers so the drivers can access the nut for tightening the straps between the tie rail and coaming rail. Then we used an electric rattle gun to tighten them and use a socket and bar at the end to confirm the tension. The two-to-one reduction in the gears on the Tightwinder is pretty impressive as it means less effort is needed to get the straps really tight. Being able to zip them up with a rattle gun makes it a quick operation too.

We’ll be installing Tightwinders on all our new trailers as they join the fleet.

TNT Australia

Transking has been a supplier to TNT for several years and during this time have provided many innovative solutions that continually provide safety and operational benefits within our operations.

Some of these solutions we have worked closely with Lindsay and the team to perfect these innovations with continual improvement.

The transport industry in Australia has and continues to benefit from the innovative products that are supplied and developed by Transking.

Neville Storey.

“...We have been operating the - Transking Quickloc System since its inception, and now have Six of the Quickloc units operating daily. The time saved using the Quickloc, quickly covers the initial cost of the system.

This to us is the best system available, but knowing Lindsay, he will continue to make improvements where possible...”

Michael Best Linfox, New Zealand

Mick was one of the original instigators of trialling and implementing the Tightwinder into the Linfox fleet in Australia followed by implementation in New Zealand.

The reason for changing to the Tightwinder is not unlike the others 1/ OH&S and 2/ effective load restraint. Mick is a complete supporter of the product, so much so that the whole Linfox NZ fleet (both new & refurb) is to be fitted with the product and is now a standard requirement. Mick believes the product best addresses a particular policy in the NZ steel industry of when using dogs and chains a bar cannot be used for injury reasons. The Tightwinder ensures necessary load restrain with minimal effort. Mick says that the NZ trucking industry is approximately 20% the size of Australia’s trucking industry however the response has been enormous. He says there is tremendous need for greater marketing activity in NZ.

Steve Hutchison Brown & Hurley

The primary attraction for Steve was the way in which the product addressed the OH&S requirement. He regularly replaces old winches with the new Tightwinder and will mix them up on a trailer. Would prefer not to but will where necessary. Steve’s refurbishment of trailers is huge market and wants to offer the best possible product to clients.

Adrian Ryan (RIP)

We have been operating the equipment for just on two years now and I am pleased to say have not had any sort of incident involving loss of load or similar. Thousands of tones of product have been moved during that time. We have a regular, detailed inspection and maintenance program designed to keep the equipment in good working order. As a result of our testing, we have been able to equip our drivers with the appropriate tension wrenches so that they know they are always applying the minimum tension required to safely restrain their loads.

I would have no hesitation in recommending the Transking product in any application where the restraint requirements were known and a safe reliable product was required.

In memory of Adrian who had significant input into the development and the upgrade of the Transking Tightwinder which has led to its success.

ADAPTERS OF TRANSKING INNOVATIONS INCLUDE

… and many more!